All Valve Industries is an environmentally responsible business.

All Valve Industries is deeply committed to fostering sustainability and improving our environmental impact. Our dedication to sustainable practices is reflected in our continuous efforts to enhance our operations, reduce energy consumption, and minimize our ecological footprint. We recognize the importance of being environmentally conscious and strive to implement solutions that benefit both our business and the planet.

In early 2013, All Valve took delivery of its first electric forklift to replace older gas-powered trucks. The move has vastly reduced our reliance on fossil fuels and minimised our carbon footprint.

We’re reducing our environmental impact through innovative product design and packaging. In 2020 we reviewed the materials used in our product and freight packaging. Since the review, over 80% of All Valve’s product packaging used is now made from recycled or recyclable materials. We have also significantly reduced the number of single-use plastics used in our warehouse, assembly, and packing lines.

We are also conscious of reducing the amount of energy we use. To this end, our state-of-the-art premises and showroom located in Sydney’s Sutherland Shire includes our unique, environmentally friendly and energy efficient RDZ radiant chilled / heated ceiling system – a first of its kind in the Southern Hemisphere, and is coupled with an energy efficient heat pump, thereby reducing energy consumption for HVAC by approximately 45%.

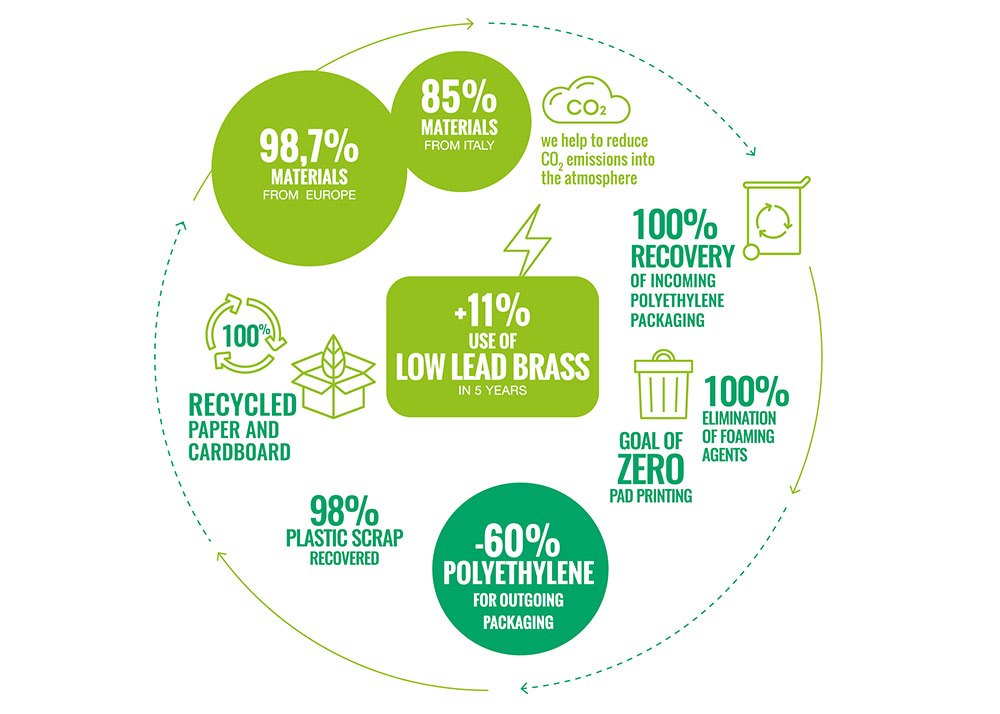

Our Italian partner, Caleffi S.p.A., no longer uses shrink wrapping. They use 6 tonnes less cellophane per year and they are able to recycle 100% of the packaging waste, which has reduced CO2 emissions as well as improving efficiency in their warehouse. Moreover, they recover nearly 100% of waste from mechanical processing, including brass scraps, oil and emulsion residue, as well as reuse and recycle up to 98.5% of their plastic scraps.